The evolution of the internal combustion engine

How to develop internal combustion engines: key dates

People are producing cars for over a century, and almost under every hood is internal combustion engine. Over the last 100 years, the principle remained the same: oxygen and fuel enter the cylinders of the engine, where the explosion (ignition), causing the inside of the power unit is formed of a force, which moves the car forward. But since the first advent of the internal combustion engine (ice) each year, engineers hone it to make faster, more reliable, more economical, more efficient.

Thanks to this, today all modern cars have become more powerful and more economical. Some conventional cars have such a capacity, which until recently was only in the powerful and expensive supercars. But without huge breakthroughs in the design of internal combustion engines, we would today still owned the greedy low-power cars that will not go far from the gas station. Fortunately, from time to time such technology breakthrough has already opened a new stage in the development of internal combustion engines. We decided to recall the most important dates in the evolution of the internal combustion engine. Here they are.

1955: fuel injection

Before injection the process of ingress of fuel into the combustion chamber of the engine was inaccurate and poorly regulated, since the fuel-air mixture supplied through the carburetor, which was in constant need of regular cleaning and periodic complex mechanical adjustment. Unfortunately, the efficiency of the carburetors was influenced by weather conditions, temperature, pressure of air in the atmosphere and even at what altitude above sea level is the car. With the advent of electronic fuel injection (injector) the fuel feeding process has become more controlled. Also with the advent injector car owners need not manually monitor the process of warming up the engine by adjusting the throttle using the “leak”. For those who don’t know what a choke:

The choke is a knob starter carb, which for gasoline cars was necessary to adjust fuel enrichment with oxygen. So, if you start a cold engine, carbureted cars need to open a “leak”, thus enriching the fuel with oxygen is more than required to warm the motor. As the warm engine should gradually close the knob of the starting device of the carburetor by returning the fuel enrichment with oxygen normal values.

See also: Here’s what actually stands for ‘compression’ and why it matters

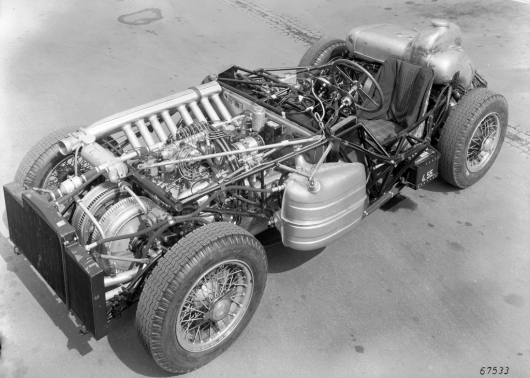

Today this technology is, of course, looks antediluvian. But more recently, most of the cars in the world were equipped with carbureted fuel systems. This is despite the fact that the technology of fuel injection using the injector came into the world in 1955, when the injector was first used on the car (previously, the fuel supply system used in airplanes).

This year it was held injector test on the road Mercedes-Benz 300SLR, which was able to drive without breaking nearly 1,600 km Is the distance the car traveled in 10 hours 7 minutes and 48 seconds. The test took place in the framework of the regular racing “a Thousand miles”. This car set a world record.

By the way, the Mercedes-Benz 300SLR was not only the first production car with fuel injection fuel injection developed by Bosch, but the fastest car in the world in those years.

Two years later, Chevrolet introduced the Corvette sports car with fuel injection system (the Rochester Ramjet). In the end, this car became faster, the discoverer of the Mercedes-Benz 300SLR.

But despite the success of the Chevrolet Corvette with a unique fuel injection system Rochester Ramjet, electronic Bosch fuel injection system (electronically controlled) started its offensive in the world. As a result, for a short time the fuel injection, designed by Bosch, began to appear on many European cars. In 1980-ies of the electronic fuel injection system (injector) swept the world.

1962: turbocharged

The turbocharger is one of the most precious stones in the internal combustion engines. The fact that the turbine, which delivers more air to the cylinders of the engine, once allowed

12-cylinder fighter during the Second world war to fly higher, to fly faster, further and to spend less expensive fuel.

In the end, like many technologies, the system of turbines of the aircraft came into the industry. So, in 1962, the world was presented the first production car with a turbocharger. They were the BMW 2002, or the Saab 99.

After which the company General Motors tried to develop this technology turbirovanie internal combustion engines in passenger cars. Thus, the vehicle Oldsmobile Jetfire came the technology of “Turbo Rocket Fluid”, which in addition to the turbine used gas cylinder and distilled water for increasing engine power. It was real fantastic. But then GM abandoned this complicated and expensive and dangerous technology. The fact is that by the end of 1970-ies, companies such as MW, Saab and Porsche, taking first place in many world racing, proved the worth of turbines in motor racing. Today, the turbine came to conventional cars in the near future, will send the usual atmospheric engines into retirement.

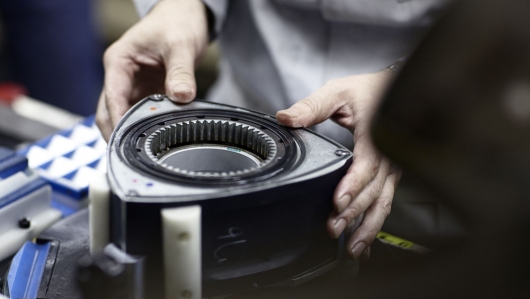

1964: the rotary engine

The only engine that really could break the mold of conventional internal combustion engine was the rotary miracle motor engineer Felix Wankel. His ice form had nothing to do with the usual engine. A rotary engine is a triangle inside an oval, rotating with diabolical force. By design, the rotary engine is lighter, less complicated and more cool, than a conventional internal combustion engine with pistons and valves.

The first rotary engines in production cars started using the Mazda and the now defunct German automaker NSU.

The first production car with a rotary Wankel engine was the NSU Spider, which was started in 1964.

The company then Mazda started the production of its vehicles equipped with rotary motor. But in 2012 she refused to use rotary engines. The latter with a rotary engine was the model RX-8.

But recently, in 2015, Mazda Tokyo motor show presented a concept car RX-Vision 2016, which uses a rotary motor. In the end, the world began to appear the rumors that the Japanese plan in the coming years to revive the rotary cars. It is assumed that at the moment the specialized group of engineers Mazda somewhere in Hiroshima sits behind closed doors and create a new generation of rotary motors, which should become the main engines in all future new models Mazda, opening a new era of revival of the company.

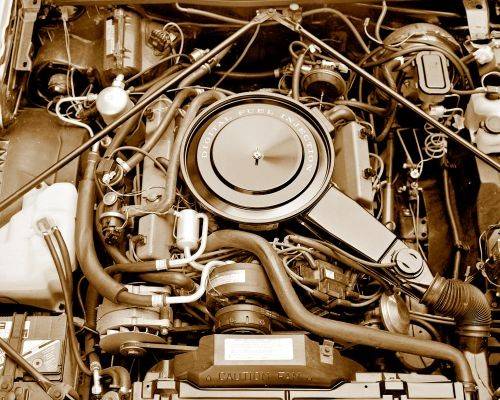

1981: technology of cylinder deactivation engine

The idea is simple. The fewer cylinders in the engine, the less fuel consumption. Naturally, the V8 engine is much hungry than the four-cylinder. It is also known that during operation of the vehicle most of the time people use the car in the city. Logically, if the car is equipped with 8 – or 6-cylinder engines, when traveling in the city all the cylinders in the engine is in principle not necessary. But how do you just turn the 8-cylinder engine in four-cylinder when you do not need to use to power all the cylinders? On this question, in 1981, decided to answer the company Cadillac, which presented the engine with cylinder deactivation 8-6-4. This motor is used the electromagnetically driven solenoids to close the valves on two or four cylinders of the engine.

This technology was to improve the efficiency of the engine, for example, when driving on the highway. But subsequent unreliability and clumsiness of the engine system with cylinder deactivation scared of all the automakers, who for 20 years was afraid to use this system in their engines.

But now that system is again beginning to conquer the world. Today, several manufacturers use this system on their production cars. Moreover, the technology has proven itself very, very well. Most interesting is that this system continues to evolve. For example, soon this technology may appear on four-cylinder and even three-cylinder engines. This is fantastic!

2012: engine with a high degree of compression – ignition gasoline, compression

Science does not stand still. If the science is not developed, then today we would still lived in the middle Ages and believed in sorcerers, fortune-tellers, and that the earth is flat (although today still, there are many people who believe in such nonsense).

Is science and in the automotive industry. So, in 2012 in the world there was another disruptive technology that may soon revolutionize the auto world.

We are talking about engines with high compression ratio.

We know that the smaller to compress the air and fuel inside an internal combustion engine, the less we will get energy in the moment when the fuel mixture ignites (explodes). Therefore, the manufacturers always tried to make motors with big compression ratio.

But there is a problem: the higher the compression ratio, the more risk of self-ignition of the fuel mixture.

Therefore, as a rule, internal combustion engines have certain limits in compression, which throughout the history of automobile industry was immutable. Yes, every engine has its compression ratio. But it does not change.

In the 1970-ies in the world was circulated unleaded gasoline, which when burned gives a huge amount of smog. In order to cope with the terrible environmental friendliness, car manufacturers started to use V8 engines with low compression ratio. It is possible to reduce the risk of spontaneous combustion of low-quality fuel in the engines and increase their reliability. The fact that when spontaneous ignition of fuel the engine can receive irreparable damage.

But then after mass emergence of electronic fuel injection manufacturers with a computer began to apply various settings that automatically adjusts the quality of the fuel mixture that significantly improve the efficiency of the engines and reduce the level of harmful substances in the exhaust. But most importantly, what has been done with computer settings and adjust the fuel mixture, is to minimize the risk of ignition of the fuel. Eventually over time it became unprofitable to use a large powerful engines with low compression ratio. So the industry introduced a new fashion – reducing the number of cylinders. To save power in motors, automakers began to use the turbine. But most importantly – thanks to the electronics that controls the quality of the fuel mixture, the manufacturers can always build engines with a high compression ratio without fear of self-ignition of the fuel.

But in 2012, Mazda has surprised the whole world, presenting a fantastic motor SKYACTIV-G, which has an incredibly high compression ratio for a production engine. The compression ratio of this motor is 14:1. This allows the motor to extract energy from almost every drop of gas without the formation of smog.

The next step for Mazda has become the new engine SKYACTIV-X, which uses controlled ignition system (SPCCI). Thanks to this system it is possible to ignite gasoline almost by mere compression. That is, as in diesel engines. In engines SKYACTIV-X has the ability to ignite the fuel in the usual way. Moreover, the electronics automatically selects, how better to ignite gasoline in the combustion chamber. It all depends on the needs of the driver and driving conditions.

For example, if you need the power (torque), the engine SKYACTIV-X will ignite the fuel from compression force (almost like diesel). If you need power, the engine with high compression will ignite the fuel in the usual way. And really to give power to be used the last drop of gasoline.

Even a century later, and even with the advent of alternative fuels, and with the advent of electric cars, internal combustion engines are the main power units in the industry. And despite the fact that many experts believe that the internal combustion engine has outlived its usefulness and should soon disappear from the world, it seems to us that the internal combustion engine is not yet developed to the end. We also believe that the world in the next 100 years will still not be ready to completely abandon the internal combustion engine running on gasoline.

And who knows what we will prepare car company in the near future. After all, their engineers knowingly receive sandwiches with black caviar. It is quite possible that soon the next automaker will surprise us with some new technology in internal combustion engines.

So too early to dismiss traditional motors. Maybe electric cars is a temporary phenomenon? Rather, it is more likely.