The five most common automotive suspensions

Here are the five most common types of suspensions

Never wondered how engineers determine and select what type of suspension needed in the car and what materials should be used in production of this suspension? Here’s the short version: the other people involved in the development of machines that tell them what to do. Engineers work in a limited suspension design dictated by the requirements for its scheme, budget and the overall architecture of the car.

Engineers are waiting for long months of painstaking calculations and dozens, hundreds included in the construction of the improvements after they are received the original data required in the vehicle design improvements and changes about the data of the kinematics and vehicle compliance with those or other purposes (SUV, sedan, sports car, commercial van).

Then the engineers, in close cooperation with designers dealing with the suspension layout and give the correct form of the diagram, the front and rear suspension in the ensemble of the whole car, customize final mounting points, add or change the bushings and silent blocks, design of levers and other variable attributes.

In the end it may be one of the five most common suspension systems of passenger cars, the variations most appropriate for that model of car.

We present you the five most common configurations of the suspension of cars:

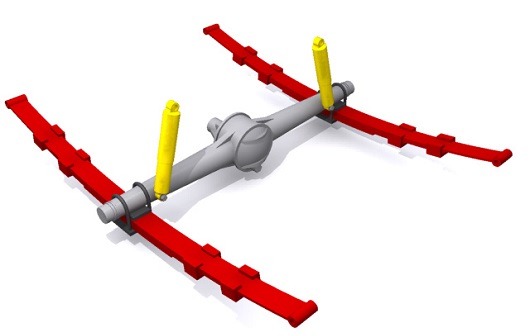

Solid axle

Brief description: Uses solid casing of the rod for fixing the wheels. The idea is as durable as the axle shaft itself, so fond of all the engineers involved in the design and development of SUVs, pickup trucks and commercial utility vehicles.

An obvious drawback of the suspension design: a bump under one of the wheels will cause you to move the opposite wheel, because they are inextricably linked. Solid axle connects the two wheels, axle, differential and axle housing. Unfortunately, all this design represents the unsprung weight of the car affecting the ride quality and impair the car’s behavior when accelerating and braking, especially in vehicles with high torque.

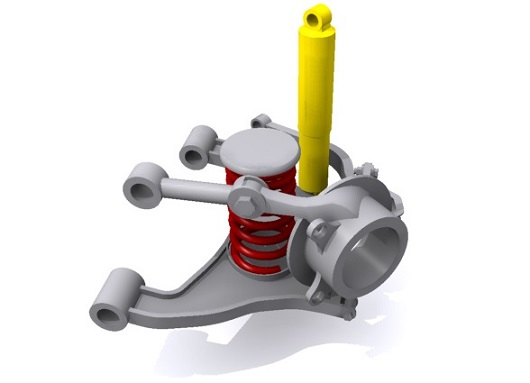

Double wishbones double wishbones

Pair of side levers, which are sometimes called double wishbones, offers better control over kinematics than McPherson.

Among the advantages: the upper arm is shorter than lower arm optimizes the orientation of the tire contact with the body roll, increasing lateral grip. The suspension is quite compact and has a smaller height than other types of suspensions. Prefer to install it under the low hood of sports cars like the Acura NSX and Chevrolet Corvette.

Multi-link suspension

The most refined and flexible settings, the type of suspension that uses a combination of many individual small arms. The amount of leverage varied and depends on what suspension setup and geometry need pendants in a variety of environments.

In the multi-link suspension system usually consists of three control arm is responsible for the lateral fixation of the wheel, one trailing link, wheel carrier in the longitudinal direction.

Implementation of the approach in multi-link suspension allows to increase the transverse rigidity and the required changes convergence with appropriate vertical and longitudinal indicators. Multi-link suspension copes with the processing loads during decelerations and accelerations, while also well behaved for high-speed maneuvers and bumps.

In General, this type of suspension is the most versatile, but unfortunately, this is one of the most expensive types of car suspensions, mainly due to the complexity of the design and lightweight materials used in the manufacture of levers.

Torsion beam

Often found in the rear suspension of budget models. This mechanism uses trailing arms and transverse elastic element, the role played by torsion.

While a torsion beam is not fully dependent suspension as a solid axle, it’s still not really an independent suspension.

Setting tighter bushings helps compensate for twisting of the beam from side to side, but for that you have to pay a greater rigidity during operation, however, in some vehicles, the used mechanism Watt or Panhard rod to improve lateral stiffness without compromising ease of movement. Low attachment points with springs and dampers, which are mounted on the suspension more than other mechanisms create conditions for a larger trunk and cargo space.

McPherson

This is the most popular type of front suspension used in all modern cars. It is a logical continuation of the development of the suspension on the two levers, but has only one (bottom), instead of the second arm is a hinge with reinforced damper with conical springs that have a double duty, dampening vertical oscillation and holding the wheel in a given horizontal plane.

The suspension design is compact and small thickness of the middle and upper part compared to the multi-link and double-wishbone suspension, which makes it ideal for cars with transverse engines. Also it is simple and cheap in construction.

However, the design of the stand limits the ability of engineers to optimize collapse.