These titanium disks have the most challenging design in the world

The first in the world printed on a 3D printer titanium wheel: welcome!

The company “HRE Wheels” introduced the world’s first printed set of 3D printer titanium wheels, with a design so unique that I want to exclaim: “This just can’t be!”

A new prototype of car wheels, have received nothing saying the name “HRE3D+”, shows how new technologies will affect the future wheel design by combining sophisticated design such an advanced material, such as titanium.

3D printing will be the main factor in the production of wheels. Why? Experts say that this is one of the most effective methods of parts production in the world at the moment. More efficient just to collect things from the atoms.

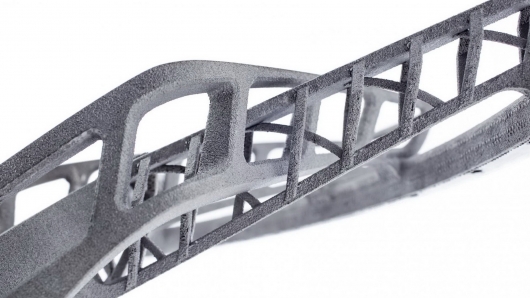

In comparison with traditional manufacture of aluminium alloy wheels where removed up to 80 percent of the material with a forged block of aluminum weighing 45 kg, making the final product in 3D printing – a complete opposite of that. It is removed and recycled just 5% of the material!

In addition, titanium is a perfect material to create the wheels, as it involves a much higher specific strength than aluminum wheels, and also resistant to corrosion. Created from it wheels extremely light, durable and able to withstand it, a very fragile design is really high loads.

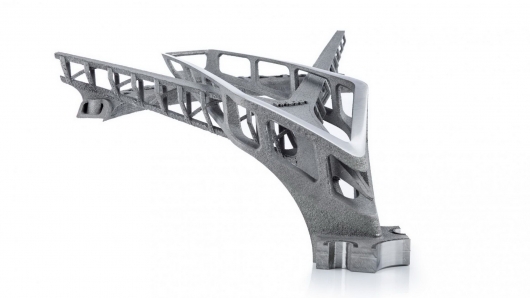

As you can see in the photo, a 3D”printed” wheel allows designers to create any design without restrictions. Any of the intricacies of the standard wheel spokes can be implemented thanks to the technology of bulk printing.

A new concept in wheel HRE3D+ was made from five separate sections, which were then combined with the Central subassembly and the rim of carbon fibre with titanium fixings. As for the design, it is, as we have said, just wild. It is absolutely not similar to anything else that you still have seen, words are not enough to describe it, remains to be seen

“This is an incredibly exciting and important project for us, because we get a glimpse of what awaits the future of design car wheels, – said HRE President Alan Peltier. – Work with a team of GE Additive AddWorks gave us access to the latest additive technology and an amazing team of engineers that allowed us to look beyond all the current possible methods”.

Video: